Automated Inventory Management 101

Automated Inventory Management, or Vendor Managed Inventory (VMI), offers both time and cost savings. Learn Automated Inventory Management basics, the steps of implementing Automated Inventory Management, and the benefits of Automated Inventory Management (AiM).

What is Automated Inventory Management?

An Automated Inventory Management System is a tool that helps businesses keep track of their stock levels automatically with minimal human intervention. Inventory Management Software is used to track stock levels in real-time, and stock is replenished as needed by an outside vendor.

What are the benefits of Automated Inventory Management?

Automated Inventory Management (AiM) or Vendor Managed Inventory (VMI) provides a number of benefits that increase your organization's efficiency. The benefits of Automated Inventory management include:

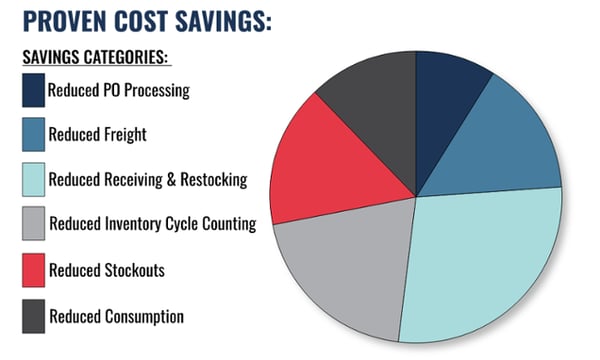

- Cost Savings: Improvements in efficiency, paired with a reduction in time required for inventory and ordering tasks, provide substantial cost savings. On average, organizations experience a 30% cost savings.

- Reduced Stock Outs: Greater visibility of real-time stock levels allow you to avoid being out of stock of the tools and supplies you need.

- Increased Accuracy: Automation and inventory software eliminates human error, the need for manual entry, and provides up-to-date data in real-time.

- Improved Efficiency And Productivity: Since automation removes the need for your team to take inventory or place orders, their time can be spent on other tasks.

- Simplified Scaling: As your business grows, inventory demands change. Automation allows for these changes to be recognized and accommodated in real time.

- Greater Traceability And Accountability: Vending systems require employee/user IDs, allowing you to accurately and directly track usage.

- Visibility And Reporting: Advanced AiM and VMI programs, including A&M Industrial's AiM program, include powerful reporting features that can monitor and analyze data ranging from product usage and location-specific usage, to spending, user history, and more.

How Does A&M Industrial's AiM Vendor Managed Inventory Program Work?

A&M Industrial's Automated Inventory Technicians will work with you to determine the optimal inventory management solution for your organization or facility. Technicians can manage your stockroom, setup your stockroom with barcoded locations, and identify minimum and maximum product stock levels. Vending machines are also available for consumables including small tools and PPE products. With over 25 years of experience implementing and maintaining inventory programs at customer sites, A&M Industrial's Automated Inventory Management (AiM) technicians can readily:

- Maintain on-site inventory inline with agreed-upon stock levels.

- Provide enhanced controls & reports on employee product consumption.

- Analyze consumption & make recommendations to optimize spend and avoid stock outs.

- Receive and stock tools and supplies at desired locations.

- Provide free product delivery.

Streamline Your Inventory Management

Want to learn more about A&M Industrials Vendor Managed Inventory Programs?