Best Abrasive For Stainless Steel

How do you choose the right abrasive solution for your application? With so many abrasive options and so many materials, choosing the right abrasive for a metalworking application can be difficult. Since Stainless Steel is such a widely machined material, in this video, we've focused specifically on what bonded abrasives are best for cutting and grinding Stainless Steel (SS).

What Are The Pros & Cons Of Stainless Steel?

Stainless Steel has a high percentage of Nickel present which gives Stainless Steel (SS) a very bright and lustrous appearance. However, this also leads us to one of the most common problems experienced when cutting Stainless Steel (SS), heat discoloration.

What Causes Heat Discoloration?

Stainless Steel (SS) doesn’t dissipate heat or friction caused by cutting well, so prioritizing wheel choice is important. By not choosing a wheel optimized for Stainless Steel, the operator may end up applying excessive pressure, increasing friction, and significantly reducing cutting speed and wheel life. These will greatly increase the cost to cut ratio, decreasing your perceived value based on a lower initial price tag.

What Abrasive Grains Are Best For Stainless Steel?

The best abrasive grains to cut and grind stainless steel include aluminum oxide, zirconia, and ceramic. Zirconia will outperform aluminum oxide in stainless steel applications. Weiler Abrasives has prioritized Stainless-Steel bonded cutting solutions that can be utilized to reduce operator fatigue, provide faster more accurate cuts, and deliver the best cost to cut return on your investment. Weiler Stainless Steel cutting solutions include Tiger Ceramic, Tiger INOX, and Tiger INOX Ultracut.

Tiger Ceramic Cutting Wheels

Tiger Ceramic Cutting Wheels are for those that prioritize putting a premium value on getting work done faster and optimized cutting wheel performance with Stainless Steel (SS). This wheel utilizes self-sharpening grains that allows the operator to cut faster with less pressure more accurately, eliminating costly rework and wasted material.

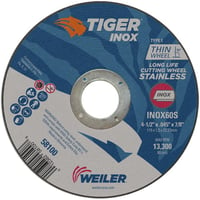

Tiger INOX Cutting Wheels

Tiger INOX Cutting Wheels are specifically designed for high performance when cutting stainless steel. These wheels incorporate a Contaminant-free bond that delivers a worry-free solution for stainless steel applications. That mean it contains less than 0.1% of Su/Cl/Fe. This is a priority for anyone doing work with Stainless-Steel utilized in Pharmaceutical, and/or Food Industries.

Tiger INOX UltraCut Wheels

Being thinner at just 1mm, Tiger INOX Ultracut Wheels will not only reduce friction increase speed of cut but it also reduces wasted steel during the cutting process. Tiger INOX UltraCut Wheels deliver unmatched cutting performance and toughness when cutting stainless steel. SOLID CORE technology increases density of the wheels, resulting in longer life, reduced friction, and superior stability. It is also a contaminant-free wheel and thus also a great option for Pharmaceutical Food Industry Industries.

Need Help Selecting The Right Weiler Abrasive For Your Application?

Need Help Selecting The Right Weiler Abrasive For Your Application?

Contact our expert metalworking team for assistance selecting the right Weiler solution for the job. In addition, download our comprehensive Weiler Abrasives Guide for in-depth selection charts and comparison tables that help you identify the right Weiler Bonded Abrasives, Weiler Flap Discs, and Weiler Power Brushes for your application.