Tungaloy Wear Problems And Solutions Chart For Carbide Inserts

Learn the cause and solution to the most common insert wear problems. Utilize the Tungaloy Insert Wear Chart to quickly identify the root cause of carbide insert wear problems including built up edge, chipping, cratering, edge deformation, flank wear, notching, and thermal cracking. Utilize the expert recommendations provided to fix the issue and optimize your machining process. Learn how to tackle the most common insert wear problems and keep your Tungaloy inserts performing at their best.

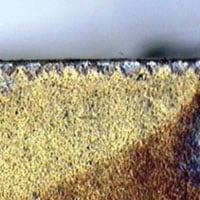

BUILT UP EDGE

Cause Of Built Up Edge:

Built up edge can be caused by excessive heat or by hard micro inclusions in the workpiece that cut into the insert. Occasionally, small pieces of the coating can break off and also cut into the insert. The cobalt then wears out and the carbide grains no longer have any adhesion, and therefore break off.

Possible Solution For Built Up Edge:

To avoid built up edge on your inserts, the following is recommended:

- Select a more wear resistant grade.

- Change the chipbreaker geometry.

- Reduce cutting speed.

- Use coolant.

CHIPPING

Cause Of Chipping:

Chipping is caused when the insert grade is too hard for application conditions.

Possible Solution For Chipping:

To avoid chipping your inserts, the following is recommended:

-

Use a tougher grade with higher cobalt content.

-

Reduce the risk of vibrations.

-

Select a larger nose radius.

-

Increase cutting speed.

CRATERING

Cause Of Insert Cratering:

Insert cratering is caused by excessive heat. In addition, cratering can occur when hard micro inclusions in the workpiece cut into the insert. Also, small pieces of the coating can break off and cut into the insert. The cobalt then wears out and the carbide grains no longer have any adhesion, and therefore break off.

Possible Solution For Cratering:

To avoid cratering on your inserts, the following is recommended:

-

Select a more wear resistant grade.

-

Change the chipbreaker geometry.

-

Reduce cutting speed.

-

Use coolant.

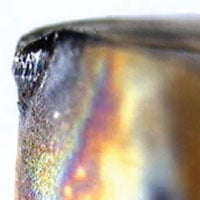

EDGE DEFORMATION

Cause Of Insert Edge Deformation:

Heavy feeds and high cutting speeds can cause edge deformation. The heat softens the insert structure, causing the cobalt to soften and the insert becomes deformed.

Possible Solution For Edge Deformation:

To avoid deforming the edges of your inserts, the following is recommended:

-

Use a more wear resistant grade.

-

Reduce cutting speeds.

-

Reduce feed.

-

Select an insert with a larger nose radius.

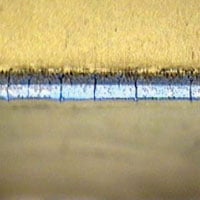

FLANK WEAR

Cause Of Flank Wear:

Flank wear occurs when the insert grade is too soft and machine speed is too fast.

Possible Solution For Flank Wear:

To avoid flank on your inserts, the following is recommended:

-

Reduce cutting speed.

-

Select a more wear resistant grade.

-

Use coolant.

NOTCHING

Cause of Insert Notching:

Notching occurs on an insert at the depth of cut line. This is usually due to work hardened surface, scale or abrasion.

Possible Solution For Insert Notching:

To avoid notching on your inserts, the following is recommended:

-

Use harder, more wear resistantgrade.

-

Reduce your cutting speed.

-

Reduce feed rate.

-

Use larger corner radius for shallow cuts.

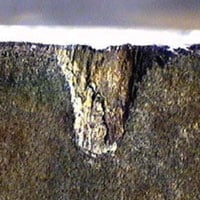

THERMAL CRACKING

Cause of Thermal Cracking:

Rapid change in thermal loads can cause thermal cracking. Temperature difference between warm and cold zones causes thermal stress which leads to cracking of the insert.

Possible Solution For Thermal Cracking:

To avoid thermal cracking on your inserts, the following is recommended:

-

Use heat resistant grades.

-

Use an abundant supply of coolant OR do not use coolant.

-

Reduce cutting speed.

-

Use positive rake tools.