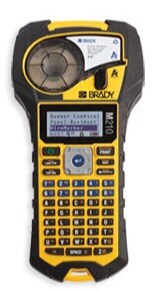

Why Every Manufacturing Facility Should Have a Brady Label Printer

In the fast-paced world of industrial manufacturing, precision and organization are paramount. Discover why a Brady label printer is an essential tool for every manufacturing facility.

Enhancing Safety and Compliance

In any manufacturing facility, safety is the top priority. Brady label printers play a crucial role in ensuring that safety standards are met by providing clear and durable labels for equipment, hazardous materials, and safety signs. These labels help to communicate vital information quickly and effectively, reducing the risk of accidents and increasing efficiency.

Moreover, Brady label printers support various compliance standards such as OSHA, ANSI, and ISO. By utilizing these printers, manufacturing facilities can easily create labels that meet the stringent requirements of these regulatory bodies, thereby avoiding costly fines and ensuring a safer work environment for all employees.

Streamlining Operations and Efficiency

Efficiency is key in manufacturing, and Brady label printers help streamline operations by making the labeling process faster and more accurate. With the ability to print labels on-demand, workers can quickly produce the labels they need without waiting for external suppliers. This reduces downtime and keeps production lines running smoothly.

Additionally, Brady label printers are designed to integrate seamlessly with existing manufacturing processes. They can be connected to databases and software systems, allowing for automated label creation based on real-time data. This integration minimizes human error and ensures that labels are always accurate and up-to-date, further enhancing operational efficiency.

Cost-Effective and Durable Solutions

Investing in a Brady label printer is a cost-effective solution for manufacturing facilities. These printers are built to last and can handle the harsh conditions often found in industrial environments. The labels produced are also highly durable, with options featuring chemical resistance, abrasion resistance, and resistance to extreme temperatures, ensuring they remain legible and intact over time.

Furthermore, by printing labels in-house, facilities can save on the costs associated with outsourcing label production. This not only reduces expenses but also provides greater control over the labeling process, allowing for quick adjustments and customizations as needed.

Versatility for Various Labeling Needs

Brady label printers offer unparalleled versatility, capable of producing a wide range of labels for different applications. Whether it’s asset tracking, cable and wire identification, or safety and warning labels, these printers can handle it all. This versatility ensures that all labeling needs within a manufacturing facility can be met with a single device, simplifying compliance, inventory management and 5S implementation, and reducing the need for multiple printers.

The printers also support various label materials and sizes, allowing for customization based on specific requirements. This flexibility is particularly beneficial in dynamic manufacturing environments where labeling needs can change rapidly.

User-Friendly Features for All Skill Levels

Brady label printers are designed with user-friendliness in mind, making them accessible to employees of all skill levels. With intuitive interfaces, easy-to-follow instructions, and pre-loaded templates, even those with minimal technical experience can quickly learn to operate the printers and produce high-quality labels.

Moreover, many Brady label printers come with advanced features such as touchscreen displays, wireless connectivity, and mobile app integration. These features enhance usability and allow for greater flexibility in label creation, ensuring that all employees can efficiently use the printers regardless of their technical proficiency.

Implementing Brady Labeling Solutions in Your Facility

Implementing Brady label solutions in your facility is a straightforward process that can yield significant safety benefits. Start by conducting a thorough assessment of your current labeling practices and identifying areas where improvements are needed. Consider the specific needs of your facility, such as the types of hazards present and the environmental conditions.

Next, contact the A&M Industrial Safety Team for help identifying the right Brady label printer and labels for your facility and applications. We can assist with product selection and train your employees on the importance of labeling and how to interpret labels. We can also help you perform regular audits and updates to your labeling system to help maintain its effectiveness, and adapt to any changes in the facility's operations.

Learn more about Brady Labelers:

A&M Industrial is a full line distributor of the Brady brand. Please call for more information on Brady Label Printers or contact the A&M Industrial Team to schedule a Brady Printer Assessment for help selecting the right label printer for your facility or application. Portable label printers can be used not only at job sites, but also throughout your facility to label and organize materials, identify part bins, contribute to your 5S efforts, and more.