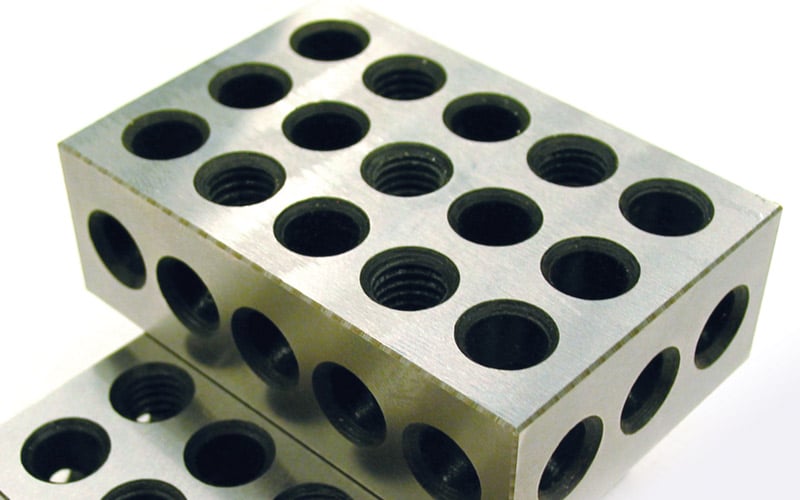

A Guide To Using 123 Blocks

When it comes to achieving accuracy and consistency in machining, 123 blocks are invaluable tools. These versatile precision measuring setup blocks, typically made of hardened steel, provide a simple yet effective means of setting up and measuring workpieces in various machining operations. In this blog, we will explore the practical applications and techniques for utilizing 123 blocks to enhance precision and streamline your machining and setup processes.

Understanding the Basics of 123 Blocks

123 blocks are named for their dimensions: 1 inch thick x 2 inches wide x and 3 inches long (1"T x 2"W x 3"L). They are commonly used in pairs, allowing for height adjustments and parallel setups. Each block has precise faces and edges that serve as reliable references for alignment and measurement. Among set-up blocks, 123 blocks are the most widely utilized, followed closely by 246 blocks (named for their dimensions: 2 inches thick x 4 inches wide x and 6 inches long (2"T x 4"W x 6"L).

How To Use 123 Blocks

Setting Up Workpieces:

-

Height Adjustment: To achieve accurate workpiece height, place one or more 123 blocks beneath the workpiece until the desired elevation is reached. These blocks can be stacked or combined with other tools like parallels to fine-tune the height.

-

Parallel Setup: When you require parallel alignment, place two 123 blocks on either side of the workpiece, ensuring their faces are in contact with both the workpiece and the machine table or vise. This arrangement guarantees consistent and level support for the workpiece.

Measuring and inspection:

-

Height Measurement: Use the thickness of a single 123 block as a reliable reference for measuring the height of a workpiece. Place the block next to the workpiece and use a height gauge or dial indicator to measure the difference in height accurately.

-

Checking Flatness: 123 blocks can also be used to verify the flatness of a surface. Place the block on the surface being checked, and using a feeler gauge or a light source, check for any gaps or light leakage between the block and the workpiece. This technique is especially useful for ensuring flatness during surface grinding or milling operations.

Squaring and Angular Setup:

-

Squaring: 123 blocks can assist in achieving precise right angles. By placing one block against the machine table or vise jaw and the other against the workpiece, you can ensure a square setup. Check the alignment with a square or precision angle block to confirm accuracy.

-

Angular Setup: For machining operations that require precise or specific angles, combine 123 blocks with other angle blocks or gage blocks to create custom setups. The combination of blocks allows you to achieve precise angular positions while easily maintaining stability.

Maintenance And Care of 123 Blocks

-

Cleaning: Regularly clean your 123 blocks with a mild solvent and wipe them dry to prevent rust or contamination. Avoid using harsh chemicals that may damage the precision surfaces or surface finish.

-

Storage: Store 123 blocks in a clean, dry, and protected environment to maintain their accuracy. Consider wrapping them in an oil-impregnated cloth or placing them in a dedicated case to prevent corrosion and damage. Many 123 block sets include a fitted protective case for safe storage and transport.

Summary

123 blocks are indispensable tools in the world of machining, offering versatility and precision in various setups and measurements. By understanding their fundamental principles and following proper techniques, you can enhance your machining processes, achieve consistent results, and reduce errors. Remember to handle and store set-up blocks, including 123 blocks, with care to ensure their longevity and accuracy. Use these modest yet effective blocks to elevate your machining, speed up set-up, and introduce unparalleled versatility to your shop.

A&M Industrial carries a variety of set-up blocks from Fowler, Suburban, Procheck, and more. Contact our metalworking team to for product selection assistance or application advice.