Automate Surface Finishing With The Autobrade Dual Head Robot Cell

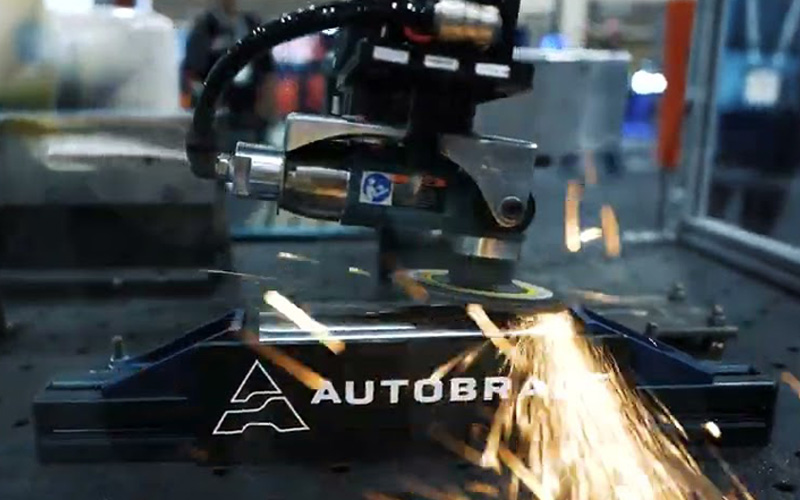

In today's fast-paced manufacturing world, precision and efficiency are essential—especially in surface finishing processes. That’s why leading manufacturers are turning to the Autobrade Dual Head Robot Cell for automated panel finishing that delivers speed, consistency, and high-quality results. Engineered with cutting-edge automation and powered by Dynabrade Robotic Finishing Tools, this dual-head system is redefining what’s possible in automated surface treatment.

What Is the Autobrade Dual Head Robot Cell?

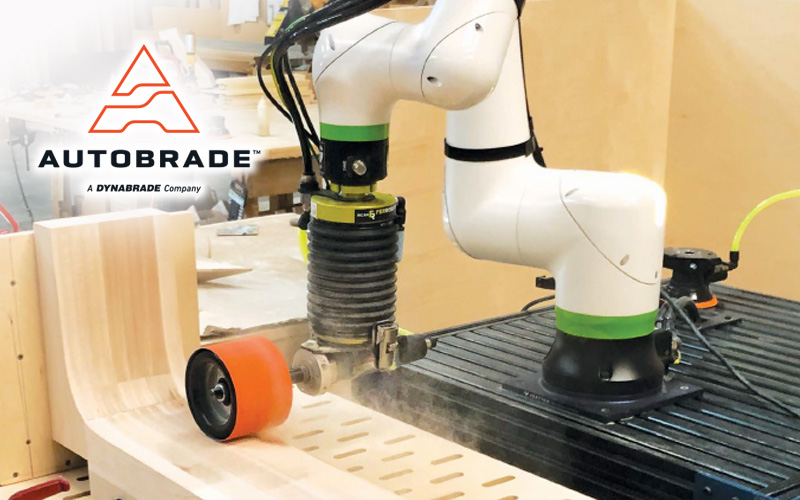

The Autobrade Dual Head Robot Cell is an advanced robotic solution developed by Dynabrade to streamline and automate large-scale panel finishing operations. Designed for maximum productivity, the cell features two synchronized robotic heads, each equipped with Dynabrade precision-engineered finishing tools. Together, they deliver consistent and repeatable surface finishing—from sanding and deburring to polishing and surface prep. With the Autobrade Dual Head Robot Cell, a single program finishes both the rail face and inner pocket using an integrated two-tool system. Easily finish with orbital fixed pad sanding and dual action random orbital action for the most consistent finish on wood, MDF and more.

Key Features of the Autobrade Dual Head Robot Cell:

- Dual robotic arms for simultaneous processing

- This unique cell uses a two tool mounting feature so no tool changing is required

- Integration with Dynabrade Robotic Finishing Tools for premium results

- High-speed, programmable finishing cycles

- Consistent pressure control for uniform surface treatment

- Suitable for flat, curved, or contoured panels

Automation That Enhances Every Surface

Surface finishing, especially on large panels, has traditionally been labor-intensive and inconsistent. The Autobrade Dual Head Robot Cell solves this by offering precise and repeatable surface conditioning, all while increasing throughput.

Benefits of Automation:

- Eliminates manual variability

- Reduces rework and quality issues

- Shortens cycle times with simultaneous dual-tool action

- Easily integrates into existing production lines

- Programmable for different panel shapes, materials, and finishes

Whether you're finishing automotive body panels, aircraft components, or metal doors, the system’s programmable intelligence allows it to adjust for part size, shape, and required surface quality, delivering consistently superior finishes.

Powered by Dynabrade Robotic Finishing Tools

What sets the Autobrade system apart is its use of proprietary Dynabrade Finishing Tools, known worldwide for their durability, precision, and innovative design. When adapted for robotic applications, these tools bring the same reliability to fully automated systems. Dynabrade offers a robust lineup of high-performance robotic finishing tools that perfectly complement the Autobrade Dual Head Robot Cell, delivering unmatched precision, consistency, and durability in automated surface finishing applications. Designed specifically for robotic integration, tools like the Dynabrade Robotic Central Vacuum Random Orbital Sander, Dynorbital Extreme Series Sanders, and Mini-Dynafile Abrasive Belt Tools provide versatile solutions for sanding, deburring, polishing, and surface preparation across flat and contoured surfaces.

Dynabrade Robotic Tool Benefits:

- Optimized for sanding, deburring, and polishing

- Compatible with Active Contact Flange Kits for consistent surface pressure

- Designed for extended tool life and minimal maintenance

- Tailored for use on metals, composites, plastics, and more

- USA-Made, delivering unparalleled quality and durability

- Dynabrade offers the widest range of pneumatic EOATs (End Of Arm Tooling)– no one has more options!

With Dynabrade tooling, your robotic cell doesn’t just automate finishing—it automates excellence.

Ideal Industries and Applications For The Autobrade Dual Head Robot Cell

The Autobrade Dual Head Robot Cell is ideal for manufacturers that produce large, flat or contoured panels in high volumes. Typical industries include:

- Automotive: Body panel preparation, bumper finishing, paint surface prep

- Aerospace: Composite skin panel sanding, metal fuselage surface prep, deburring and edge blending

- Metal Fabrication: Sheet metal finishing, door and panel smoothing, weld cleanup and blending

Whether you're finishing aluminum, steel, fiberglass, or composite materials, the Autobrade Dual Head Robot Cell ensures top-tier finish quality with every pass.

Seamless Robotic Integration

The system is designed to integrate with leading robotic platforms including FANUC, Universal Robots, Doosan, and more. This compatibility ensures flexible deployment across a wide variety of robotic manufacturing environments.

Final Thoughts

If your production line involves large-panel surface finishing, the Dynabrade Autobrade Dual Head Robot Cell is the smart automation solution you’ve been waiting for. With dual-action robotic arms, Dynabrade best-in-class finishing tools, and seamless automation, you’ll achieve faster cycles, improved finish consistency, and higher production output—all while reducing labor and operational costs. Autobrade Solutions provide automated finishing, consistent quality and the industry-best performance Dynabrade is known for. For a demo, or more information on Autobrade, contact the A&M Industrial Robotics Team or visit www.autobrade.com