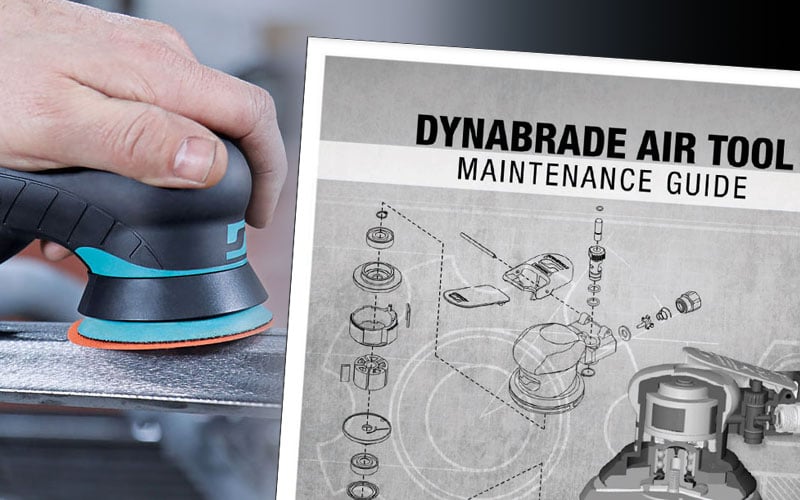

Downloadable Dynabrade Air Tools Maintenance Guide

How Do You Maintain Dynabrade Air Tools?

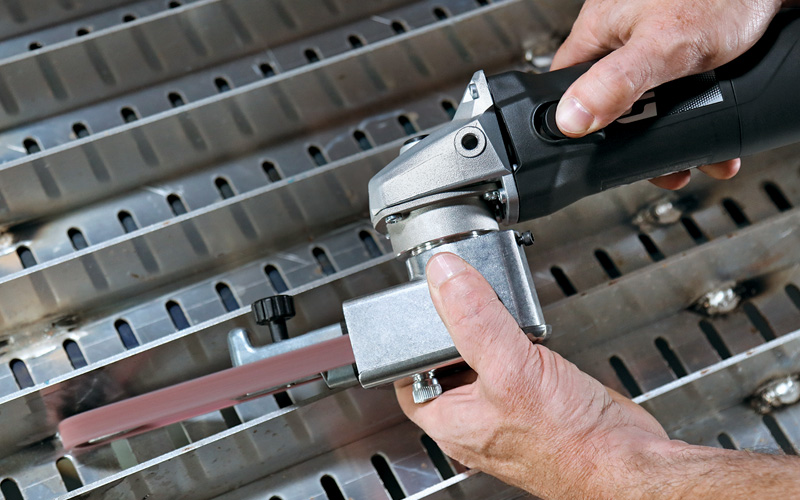

Air tool maintenance is essential to keep your air tools performing well. Regular maintenance of your Dynabrade pneumatic tools can significantly extend the lifespan of your Dynabrade air tools, reduce the risk of wear and tear, and ultimately save you from costly repairs or replacements down the line. The Dynabrade Air Tool Maintenance Guide features instructions and expert recommendations including:

- How to select a compressor

- Air tool preventative maintenance

- How CFM is defined

- How to maintain adequate air flow for your air tools

- How to choose the right air supply hose for your application

- Air supply hose recommendations

- How to lubricate the air motor

- How to install an air tool drop-in motor

- Air tool and air system inspection & diagnosis

- Air system checklist

- Random orbital sander swirl-free checklist

- Air tool repair tools and part listings

Want To Learn More About DynaBrade AIr Tools

Our latest Dynabrade Catalog features best-selling Dynabrade solutions, including Dynabrade air tools, power tools, machinery and vacuums. Contact the A&M Industrial Metalworking Team for additional expert support. Our experienced team can help you troubleshoot any metalworking or machining challenges, provide speed and feed recommendations, and identify opportunities to reduce cycle times and increase efficiency. The team can also assist you with Dynabrade Air Tool troubleshooting and maintenance.

Our latest Dynabrade Catalog features best-selling Dynabrade solutions, including Dynabrade air tools, power tools, machinery and vacuums. Contact the A&M Industrial Metalworking Team for additional expert support. Our experienced team can help you troubleshoot any metalworking or machining challenges, provide speed and feed recommendations, and identify opportunities to reduce cycle times and increase efficiency. The team can also assist you with Dynabrade Air Tool troubleshooting and maintenance.