Essential Dynabrade Dynafile Maintenance Tips

Learn how to keep your Dynabrade Dynafile in peak condition with these comprehensive Dynafile maintenance tips, ensuring its longevity and optimal performance.

The Importance of Cleaning Your Dynafile Regularly

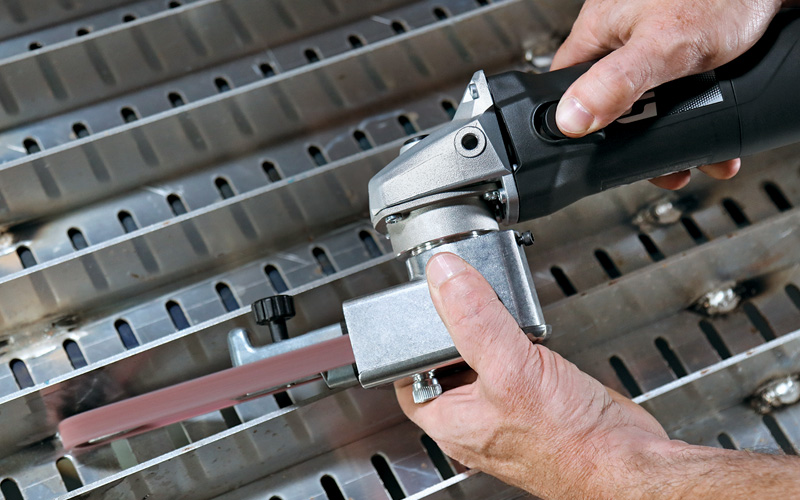

Maintaining the cleanliness of your Dynafile, Dynafile II, Dynafile III or Mini-Dynafile II is the first step in ensuring its longevity and optimal performance. These abrasive belt tools are often used in environments filled with dust and debris, such as workshops and construction sites. Over time, these particles can accumulate on and inside the tool, leading to decreased efficiency and potential damage.

To prevent this, make it a habit to clean your Dynafile abrasive belt tool after each use. Use a soft, dry cloth to wipe down the exterior, removing any dust or debris. Additionally, consider using compressed air to blow out any particles that may have entered the tool. Regular cleaning not only prevents buildup that can hinder the tool's operation but also helps maintain its overall performance and durability.

Proper dynafile Lubrication Techniques for Optimal Performance

Lubrication is a critical aspect of maintaining your original Dynafile. Proper lubrication reduces wear and tear on moving parts, minimizes friction, and ensures smooth operation. It is recommended to lubricate your Dynafile before each use, especially if it will be in operation for extended periods.

To lubricate your Dynafile, Dynafile II, Dynafile III or Mini-Dynafile II, use a high-quality air tool lubricant, such as Dynabrade Air Lube. Apply one drop of lubricant per minute for every 10 SCFM of air consumption. For instance, if your tool operates at 40 SCFM, set the drip rate to 4 drops per minute. This ensures that the internal components are consistently lubricated during use. Additionally, for more automated maintenance, consider installing a Filter-Regulator-Lubricator (FRL) system. This system automatically adds oil to the compressed air, making it easier to maintain the proper lubrication levels and ensuring that the air entering the tool is clean and dry.

Effective Dynafile Storage Solutions For Tool Longevity

Storing your Dynafile, Dynafile II, Dynafile III or Mini-Dynafile II correctly is essential to prevent damage and ensure it remains in optimal condition. Always store your air tools in a dry, dust-free environment. Use storage boxes or bags to protect them from dirt, moisture, and physical damage. Avoid exposing your Dynafile to extreme temperatures, as this can affect its performance and longevity.

When not in use, disconnect the tool from the air supply and store it in a manner that prevents it from being knocked over or dropped. Consider using tool rests, hangers, or balancers to keep your Dynafile, Dynafile II, Dynafile III or Mini-Dynafile II securely in place. Proper storage not only protects the tool from environmental damage but also makes it easier to locate and access when needed.

Handling Your Dynafile With Care

Handling your Dynafile abrasive belt tool with care is crucial to its maintenance. Avoid dropping the tool or knocking it against hard surfaces, as this can cause internal damage or misalignment of components. When carrying the tool, always use the designated handles and do not carry it by the air hose, as this can lead to hose damage and air leaks.

Regularly inspect the air hoses and fittings for signs of wear and tear. Replace any damaged or worn components to maintain a secure and efficient air supply. Additionally, blow out the air supply hose before initial use to remove any debris that may have accumulated. Taking these precautions ensures that your Dynafile remains in good working condition and reduces the risk of accidents or malfunctions.

The Importance Of Using Genuine Dynabrade Replacement Parts

Using genuine Dynabrade replacement parts is essential for maintaining the quality and performance of your original Dynafile. Non-genuine parts may not meet the same standards and can lead to subpar performance or even damage the tool. When ordering replacement parts, always specify the model number, serial number, and RPM of your air tool to ensure you receive the correct components.

Genuine Dynabrade parts are designed to fit perfectly and work seamlessly with your Dynafile, ensuring that it continues to operate at its best. Additionally, using authentic parts helps to maintain the tool's warranty and provides peace of mind knowing that you are using products that meet the manufacturer's specifications.

Benefits Of A Filter-Regulator-Lubricator System

A Filter-Regulator-Lubricator (FRL) system is highly recommended for maintaining your original Dynafile and other rotary vane air tools. An FRL system provides several benefits that contribute to the tool's longevity and performance. It regulates air pressure, ensuring that the tool receives the optimal amount of air for efficient operation. The system also filters out water and contaminants, preventing them from entering the tool and causing damage.

By automatically adding oil to the compressed air, an FRL system ensures that your Dynafile remains properly lubricated at all times. This reduces the need for manual lubrication and helps to maintain consistent performance. Installing an FRL system is a proactive step in maintaining your Dynafile, making it easier to manage and extending the life of your tool.

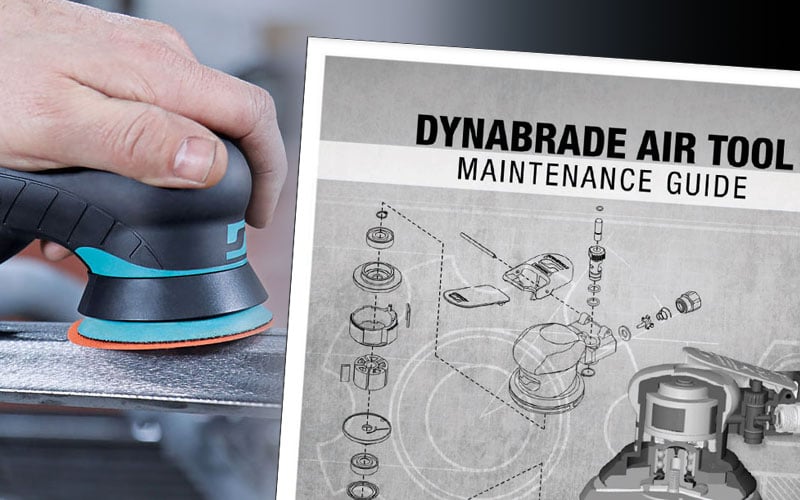

In conclusion, regular maintenance, proper lubrication, careful handling, and the use of genuine parts are essential for keeping your original Dynafile in top condition. By following these tips, you can ensure that your Dynafile remains a reliable and efficient tool for years to come. Download the Dynabrade Maintenance Guide for expert recommendations and tips on preventative maintenance and care of compressed air supply systems, compressors, air supply hoses, and air tools. Learn how to inspect and diagnose pneumatic tools and your air system, effectively increasing your efficiency, reducing costs, and ensuring each Dynabrade air tool's optimal performance.