Exploring the Features of the Nachi AQUA EX Flat Drill

Unlock unparalleled precision and efficiency with the advanced NACHI AQUA EX Flat Drill, ideal for flat bottom applications in the oil and gas, automotive and medical industries.

Innovative Design and Construction

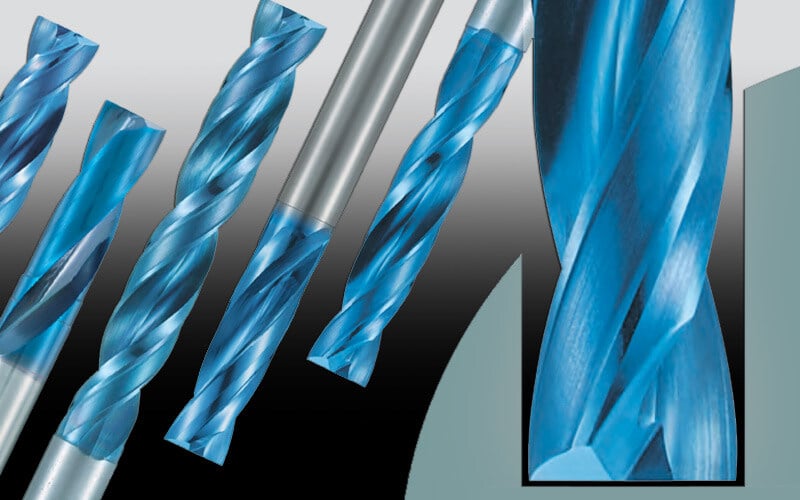

The NACHI AQUA EX Flat Drill stands out with its innovative design and robust construction. Engineered to meet the rigorous demands of industrial manufacturing, this innovative drill features a flat geometry, true 180º flat cutting edge that ensures minimal burrs, optimal chip evacuation, and minimal deflection. The drill's unique design not only enhances its performance but also significantly reduces the risk of tool breakage, making it a reliable choice for various machining tasks.

Crafted from high-quality materials, the NACHI AQUA EX Flat Drill boasts exceptional hardness and toughness. Its advanced coating technology further enhances its durability, providing superior resistance to wear and heat. This meticulous attention to detail in design and construction ensures that the drill performs consistently, even under the most challenging conditions.

Unmatched Precision and Accuracy

When it comes to precision and accuracy, the NACHI AQUA EX Flat Drill is in a league of its own. The drill's flat geometry and sharp cutting edges ensure clean, precise holes with minimal burrs. This level of accuracy is crucial in industrial manufacturing, where even the slightest deviation can lead to costly errors and rework.

The drill's superior design also contributes to its excellent centering capabilities, reducing the need for pilot holes and simplifying the drilling process. Whether you're working with steel, stainless, or non-ferrous materials, the NACHI AQUA EX Flat Drill delivers reliable, repeatable results, making it an indispensable tool for any machining operation.

Enhanced Durability and Longevity

Durability and longevity are key considerations for any industrial tool, and the NACHI AQUA EX Flat Drill excels in both areas. Its high-quality construction materials and advanced AQUA EX coating technology provide exceptional resistance to wear, heat, and corrosion. This means that this high performance drill maintains its sharpness and effectiveness over extended periods, reducing the frequency of tool changes and downtime.

Moreover, the drill's robust design minimizes the risk of breakage, even when subjected to high-speed drilling or heavy feed rates. This reliability ensures that the NACHI AQUA EX Flat Drill remains a cost-effective solution for industrial manufacturers, delivering consistent performance and lasting value.

One Drill Does It All

The versatile NACHI AQUA EX Flat Drill eliminates the need to use a center drill or end mill on inclined or curved surfaces, allowing one step drilling with minimal burr. Its ability to handle a wide range of materials, from metals and alloys to plastics, allows manufacturers to streamline their tooling inventory and reduce costs. The drill's precision and reliability make it suitable for applications such as aerospace, automotive, medical, and general engineering, where high standards of quality and accuracy are essential.

In addition to its material versatility, the NACHI AQUA EX Flat Drill is also compatible with different machining operations, including CNC machining and automated production lines. This adaptability ensures that the drill can meet the diverse needs of modern industrial manufacturing and metalworking, providing a flexible and efficient solution for various drilling tasks.

NacHi AQUA EX Flat Drills Versus End Mills

How is a flat bottom drill different than an end mill? At first glance, a flat bottom drill may appear similar to an end mill, but they have distinct differences. Firstly, it is designed for end cutting only. The peripheral edges are not meant for cutting, so flat bottoms are used solely for axial direction cuts. The radial margins help stabilize the drilling process. Additionally, the fluting on a flat bottom is crafted to remove chips like a drill. The large fluting allows chips to flow upward out of the hole, unlike an end mill, which disperses chips to the side during cutting. End mills can lead to surface finish issues inside a hole due to their chip removal method, whereas a flat bottom drill efficiently evacuates chips, leaving a smooth, consistent finish. Finally, the flat bottom is truly flat, with a point angle of 180°, while an end mill typically has a 2° dish angle. The design of a flat bottom drill enables the creation of true flat surfaces without the need for interpolation.

Boosting Productivity and Reducing Costs

One of the primary benefits of the NACHI AQUA EX Flat Drill is its potential to boost productivity and reduce costs in industrial manufacturing. The drill's versatility allows for use over a wide range of applications and materials, requiring less change outs, while the drill's precise cutting action and efficient chip evacuation allow for higher speed and feed rates, minimizing cycle times and increasing throughput. This improved efficiency translates into higher production volumes and reduced labor costs, enhancing overall operational profitability.

Furthermore, the drill's durability and longevity reduce the need for frequent tool changes and maintenance, lowering operational costs and minimizing downtime. By investing in the NACHI AQUA EX Flat Drill, manufacturers can achieve significant cost savings while maintaining high standards of quality and machining performance.

Learn more about Nachi AQUA EX Flat Drills

Download our comprehensive NACHI AQUA EX Flat Drill guide to learn more about this innovative drill's features, view vendor recommendations, and see the full line of NACHI AQUA EX Flat Drills. For assistance selecting the right NACHI AQUA EX Flat Drill for your application or material, contact the A&M Metalworking Team.