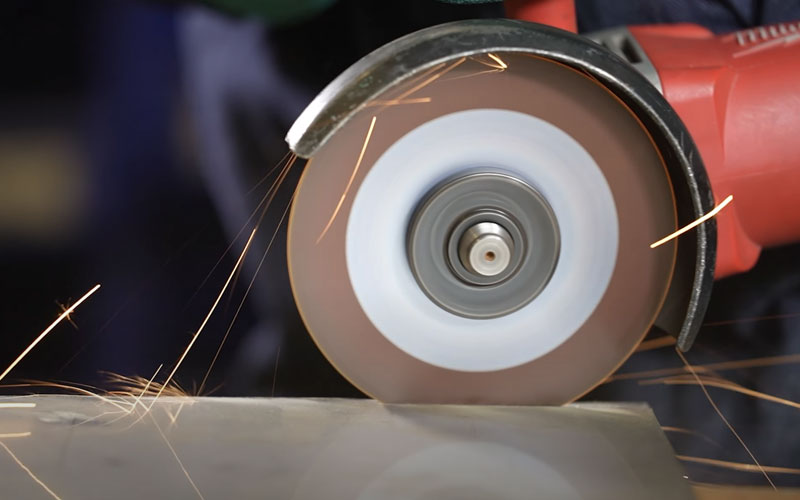

How To Choose the Right Fiber Disc for Your Application

Fiber discs are a go-to solution for grinding and finishing, offering performance that rivals grinding wheels—if you choose the right disc for your material and application. Here’s what you need to know:

What Is a Fiber Disc?

A fiber disc is a coated abrasive bonded to a vulcanized fiber backing. United Abrasives/SAIT offers options ranging from general-purpose discs to premium versions with grinding aids that reduce heat and loading—ideal for stainless steel, aluminum, and high-pressure applications. SAIT discs feature industry-best backing resists tearing and curling, providing durability, aggressive cutting, and extended life. The rigid vulcanized fiber backing enables use in high-pressure, aggressive applications—outperforming cloth or paper-backed discs in stock removal.

Why Backing Pads Matter

Fiber discs MUST be mounted with a backing pad, which provides necessary support and prevents tearing. Popular options include:

- Spiralcool™ Pads: Spiral ribs promote airflow for cooler grinding and up to 50% longer disc life.

Choosing the Right Abrasive Grain

The abrasive grain determines speed, life, and value. SAIT offers four main types:

Aluminum Oxide (A/O):

Affordable and versatile.

- AO: Open-coat for general purpose grinding and finishing.

- 2A: Closed-coat for general purpose grinding and finishing of ferrous and non-ferrous metals.

- 3A: Closed-coat with a grinding aid for general purpose grinding of stainless steel and aluminum.

Zirconium (Z):

Longer life under high pressure applications including blending, deburring and weld removal.

- AZX: Economical, fast grinding and finishing.

- Z Closed-coat: Aggressive stock removal and long life on ferrous and non-ferrous metals.

Ceramic (C):

Ceramic grain delivers top-tier performance with fast, efficient material removal and fewer disc changes. Its self-sharpening structure offers increased cutting power, cooler grinding, and reduced friction—ideal for carbon steel, high-tensile alloys, and heat-sensitive materials.

7S – Closed-coat: Delivers aggressive stock removal and long life on carbon steel and alloys; excels under high pressure.

9S – With Grinding Aid: High-performance option for grinding stainless steel and aluminum.

7-II: Premium disc for carbon steel and ferrous metals—ideal for welds, burrs, and heavy stock removal.

9.3: Top-tier disc for stainless steel, high-alloyed steels, and aluminum—grinding aids for reduced heat and loading and allows for cool cutting.

Silicon Carbide (SiC):

Silicon carbide’s sharp, sliver-like grain cuts quickly and aggressively, making it ideal for grinding stone materials like concrete, marble, and granite. Its brittle structure also excels on hard metals such as cast iron, carbide, and titanium.

C Closed-coat: Excellent for stone, cast iron, titanium—available in 7" from 16–400 grit with recessed center hole that prevents the locking nut from marring the workpiece.

Conclusion

Choosing the right fiber disc is essential for maximizing efficiency, achieving a quality finish, and extending the life of your abrasives. The correct grain type, grit size, and backing pad can significantly impact performance, reduce downtime, and lower overall costs. Whether you're working with metal, stone, or composites, selecting the best United Abrasives/SAIT fiber disc for your specific material and application ensures safer, faster, and more effective grinding results. For assistance selecting the right fiber disc for your application, contact the A&M Industrial Metalworking Team.