Ladder Safety 101

During A&M Industrial’s 2019 Safety Symposium, it was brought to our attention that many people wanted to learn more about general ladder safety and best practices. Our safety team compiled the following to answer the most common questions we get asked about proper ladder storage, ladder maintenance, ladder inspections and ladder safety. These safety recommendations apply to step ladders, extension ladders, and platform ladders.

What Are Some General Ladder Safety Recommendations?

Before each use, inspect the ladder and be sure to adhere to the following ladder best practices:

- Choose the proper ladder length: On most ladders, you cannot use the topmost rung. Make sure the second-highest step will give you adequate access to what you need to reach.

- Use a ladder with the right load capacity & duty rating for the job: Do not load ladders beyond their maximum intended load nor beyond their manufacturer’s rated capacity.

Type

Duty Rating

Use

Load

IAA

Special Duty

Rugged

375 lbs.

IA

Extra Duty

Industrial

300 lbs.

I Heavy Duty

Industrial

250 lbs.

II Medium Duty

Commercial

225 lbs.

III Light Duty

Household

200 lbs.

- Mind (and close!) the gap: If you're using a ladder to climb up to a point where you will step off the ladder and onto a roof or structure, make sure the ladder extends three feet higher than the upper support point. If there is a gap between the top of the ladder and the step point, you run the risk of falling and being injured. Also, be sure to position your ladder as close to the work area as possible. If you have to lean to reach the work area, you risk losing your balance and falling.

- Check an extension ladder's overlap: make sure the top of the ladder does not extend more than three feet beyond the upper support point. Excess overlap can act as a lever and cause the base of the ladder to swing out from beneath you.

- Be sure the ladder is on a flat, even surface: Your ladder's feet must sit flat against even ground to ensure it is properly balanced and will not wobble or fall.

- Work at a safe ladder angle: When utilizing a straight ladder or an extension ladder, follow a 1:4 ratio with 75° tilt. For example, if you are using a 24' ladder, you would sit the ladder 6' away from the support point.

- Be careful and deliberate: When working on a ladder, be sure you are wearing slip-resistant shoes, position yourself at the center of each step or rung, and maintain 3-points of contact (two hands and a foot, or two feet and a hand) when climbing/descending a ladder. Be sure to be facing the steps or rungs when you are ascending or descending the ladder, and move slowly and deliberately to avoid mis-steps or loss of balance.

-

Never carry tools in your hands while climbing up/down a ladder: Carry tools in a tool belt or raise tools up using a hand line.

What do you look for when inspecting a ladder?

Ladders need to be inspected by a qualified person for visible defects before each use, understanding that a ladder is continually exposed to conditions that may impact its integrity. Prior to usage, all ladders should be inspected for the following:-

Ladders should be free of any visible damage, including cracks, dents, chips or splinters in the ladder rails.

-

Ladder parts should not be loose - all hardware and fittings must be securely attached.

-

Ladder steps or rungs should be tight and secure to the side rails.

-

Movable parts must be tested to see that they not overly loose and that they can operate without binding.

-

All ladder safety labels should be intact and readable.

-

Ladders must not be slippery– be sure ladders are free of oil and grease. Clean any visible liquid, particles or residue from ladder steps to preserve traction.

-

The ladder has level footing, with a slip resistant ladder base. The rubber covers on ladder feet are integral to slip-prevention. Inspect them to ensure they aren't cracked or worn.

When is it the right time to replace a ladder?

While ladders don't noticeably wear out like other tools will, they definitely do need to be inspected regularly and replaced when their lifespan ends. You should always check your ladders before use for cracks, bends or breaks in any part of the ladder. If you find any of these defects, do not use the ladder and tag it for removal and replacement, regardless of how "new" the ladder may look or be. Remember that there is no expiration date for ladders, so as long as you follow proper storage techniques and treat it with care, your ladder could last you an extremely long time.

How long will a fiberglass ladder last having faced prolonged exposure to varying weather conditions?

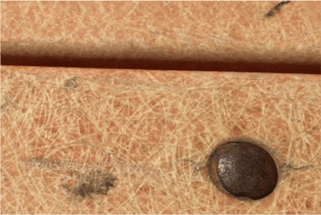

You might be asking yourself this question after weighing the pros and cons of the aforementioned storage solutions, so let’s clear this one up for you. To understand a fiberglass ladders' lifespan, we should first understand the main killer of these ladders: the sun. Prolonged sun exposure will damage the fibers the ladder is made of. At first, this constant blast of UV rays will expose the fibers, which is only aesthetic. According to the Occupational Safety & Health Administration, over time, this will cause an event called fiber bloom. Fiber bloom is structural damage and requires the ladder to be replaced, which is why ladder inspection before use is critical, regardless of ladder age. You can request a ladder inspection here, and reference the adjacent image illustrating fiber bloom, so you know what to look out for when performing your own inspections on fiberglass ladders.

Why are wooden ladders a poor choice of ladder?

This is one of the most common ladder questions brought to our attention! Wood ladders are susceptible to cracks, rot, splinters, broken rungs, loose joints and bolts, and hardware in poor condition. These issues consistently occur because wood expands and contracts in hot and cold weather, and can also absorb water, causing structural instability over time. Aluminum or fiberglass ladders are recommended over wood ones, as aluminum ladders and fiberglass ladders typically have a longer lifespan and require less maintenance vs. their wood counterparts.

If you insist on using wooden ladders, protect them with a clear sealer varnish, shellac, linseed oil, or wood preservatives. Wood ladders should never be painted, as the paint will hide defects and cause an unsafe work environment.

What are the best ladder storage solutions available?

Ideally, you want to store your ladders in a location that is safe, secure, and protected from outside factors. This will leave you with two options that can realistically be used, with pros and cons to both. These options would be a garage/warehouse or ladder racks on a truck.

Ideally, you want to store your ladders in a location that is safe, secure, and protected from outside factors. This will leave you with two options that can realistically be used, with pros and cons to both. These options would be a garage/warehouse or ladder racks on a truck.

Using a garage or warehouse to store your ladders indoors is the absolute best in terms of location, as your ladders are protected from the outside environment and are secure. There can be, however, a downside to storing ladders in an indoor location – namely, the time spent loading and unloading step ladders or extension ladders daily from job sites, or on and off trucks or work vans. In addition, ladders take up valuable warehouse space when not in use. For those that don't think an indoor storage option is right for them, there is an alternative.

Leaving ladders racked on a truck is a good compromise between convenience and security. While this solution doesn't protect your ladders from the sun, rain and snow, it does keep them safe and secure. While the lifespan of your ladders will be shortened from the prolonged outside exposure this solution has, the convenience it offers can be worth more to customers, making it just as viable a solution. Regardless of what storage solution you choose, remember to always inspect your ladder before use and replace it when damage is found.

Where can I find more information regarding OSHA regulations for ladder safety?

The grim reality is, falls are the leading cause of death in the construction industry, with ladder falls accounting for 1/3 of these deaths. You owe it to yourself and your employees to stay safe by following OSHA-recommended safety practices. Download our Ladder Safety Guide for more information and recommendations. Contact the A&M Industrial Safety Team to schedule a ladder inspection, perform respirator fit testing, implement Lockout Tagout, and more.