Overhead Sling Safety: What to Look For And When To Replace

Ensuring the safety of an overhead sling is crucial when it comes to lifting heavy loads. Overhead slings are commonly used in various industries including construction, manufacturing, and warehousing, to lift and transport heavy objects. However, using a faulty or unsafe overhead sling can lead to accidents, injuries, and damage to the load being lifted. Therefore, it is essential to understand the importance of overhead sling safety and know how to identify signs of a safe overhead sling. In this blog, we'll discover the key indicators that ensure the safety of an overhead sling while lifting heavy loads.

the Importance of Overhead Sling Safety

When an overhead web sling is safe for use, it provides a reliable and secure means of lifting heavy objects. It minimizes the risk of load failure, ensures the stability of the load, and protects the workers involved in the lifting operation. By following proper safety guidelines and inspecting the sling before each use, you can prevent accidents and maintain a safe working environment.

Inspecting the Material and Construction

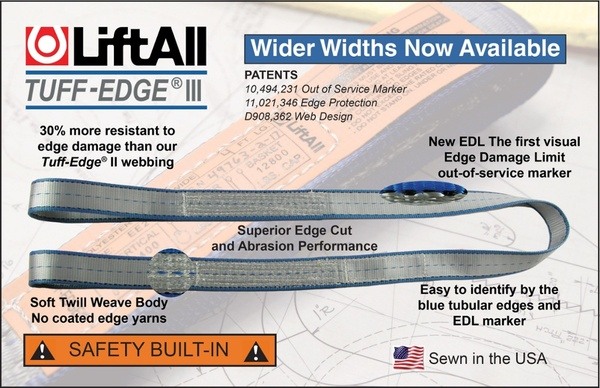

One of the first things to consider when determining the safety of an overhead sling is its material and construction. The sling should be made from high-quality materials that can withstand the weight of the load and resist wear and tear. Common materials used for overhead slings include nylon, polyester, and steel. These materials have different load capacities and properties, so it is important to choose the right material based on the specific lifting requirements.

Additionally, the construction of the sling should be carefully inspected. Look for any signs of damage, such as cuts, tears, or frayed edges. Check the stitching and reinforcements to ensure they are intact and secure. Any signs of wear or damage can compromise the strength and safety of the sling, so it is important to replace it if any issues are found.

Refer to the following videos for how to properly examine each of the following:

Checking for Proper Load Capacity

Another crucial aspect of overhead sling safety is checking for proper load capacity. Each overhead sling has a specific load capacity that it can safely handle. Exceeding the load capacity can lead to sling failure and accidents. Therefore, it is important to know the weight of the load being lifted and ensure that the overhead sling has an adequate load capacity to handle it.

To determine the load capacity of an overhead sling, check the manufacturer's specifications or markings on the sling itself. These markings indicate the working load limit (WLL) or the maximum weight the sling can safely support. Make sure to choose a sling with a load capacity that exceeds the weight of the load being lifted to provide a safety margin.

Examining the Stitching and Reinforcements

The stitching and reinforcements of an overhead sling play a crucial role in its safety and reliability. Inspect the stitching to ensure it is tight, even, and free from any loose threads or gaps. The stitching should be done with high-quality thread that is resistant to abrasion and damage. Additionally, check for reinforcements at critical points, such as the eyes or loops of the sling. Reinforcements enhance the strength and durability of the sling, so it is important to ensure they are present and in good condition.

If any stitching or reinforcements are damaged or show signs of wear, it is essential to replace the sling immediately. Using a sling with compromised stitching or reinforcements can lead to catastrophic failure during a lifting operation.

Looking for Certification and Compliance

When selecting an overhead sling, it is important to look for certification and compliance with industry standards. A certified sling indicates that it has been tested and meets specific safety requirements. Look for certifications from reputable organizations, such as the Occupational Safety and Health Administration (OSHA) or the International Organization for Standardization (ISO). These certifications ensure that the sling has undergone rigorous testing and meets the necessary safety standards.

In addition to certification, check for compliance with relevant regulations and guidelines. Different industries may have specific requirements for overhead slings, so it is important to ensure that the sling meets all the necessary regulations. This can include requirements for labeling, documentation, and periodic inspections.

LIFT-ALL Sling Shelf-Life

The shelf life of Lift-All Slings is considered to be indefinite unless they are exposed to any degrading chemicals or vapors, if synthetic slings are exposed to elevated temperatures above 200 degrees Fahrenheit, or to any significant UV light. Tests performed on slings several years old, and tests performed on aged nylon and polyester yarn suggest that these materials are not affected by age to any observable degree. Regarding ultraviolet light exposure, all organic fibers, whether natural or man-made, will degrade to various degrees from exposure to ultraviolet light. As stated in warning information provided with each sling made from synthetic material, these slings should be stored away from sunlight, fluorescent light, and other sources of ultraviolet radiation when not in use.

If slings have been shelved or stored in a proper manner for several years, Lift-All Slings can be placed back into service, provided no visible damage is apparent upon inspection. Should you want further assurance of the sling integrity, you have the further option of having them proof tested or by having Lift-All perform a sample destructive tensile test to failure of one or more Lift-All Slings.

Conclusion

By choosing a certified and compliant overhead sling, you can have peace of mind knowing that it has been tested and meets the highest safety standards. Following manufacturer guidelines, adhering to noted lift capacity, and properly storing your slings away from high heat, chemical exposure, UV light, and radiation, is necessary to ensure both the integrity of the sling and the safety of your team. For further assistance selecting the right sling for your application, or should you have additional questions, please contact the A&M Industrial Material Handling Team.