Microcut Abrasion Resistant Coatings: Enhancing End Mill Performance

In the world of high-performance machining, where tool longevity and cutting precision are critical, USA-Made Microcut end mills stand out for their exceptional quality, durability, and innovative coating technologies. Designed to thrive in the most demanding conditions, Microcut’s advanced abrasion-resistant coatings—including Titanium Carbonitride (TiCN), Zirconium Nitride (ZrN), Aluminum Titanium Nitride (AlTiN), AlTiSi-based nanocomposite coating (nACo), and Diamond—are meticulously engineered to combat wear, a leading cause of tool failure during high-speed, high-friction operations. These coatings enhance hardness, reduce thermal stress, and provide superior lubricity, enabling Microcut tools to maintain sharp edges and consistent performance across a broad range of materials, from hardened steels to abrasive composites and soft non-ferrous metals. In this blog, we’ll explore each of these coating technologies, their properties, and the metalworking applications where they truly shine.

What Is Abrasion Resistance?

Abrasion resistance is a material's ability to withstand wear and tear caused by friction, rubbing, or scraping against another surface. It's crucial for the durability and lifespan of cutting tools.

Coatings that resist abrasion are engineered to withstand wear, improving edge retention and cutting performance while minimizing tool degradation.

Microcut Abrasion-Resistant Coatings:

Titanium Carbonitride (TiCN) Coating

Titanium Carbonitride (TiCN) Coating

Color: Blue-gray

Hardness: ~3,000 HV

Max Operating Temp: ~400–450°C

Friction Coefficient: Lower than TiN

Key Features of TiCN Coating: TiCN offers superior hardness compared to traditional TiN (Titanium Nitride), making it more resistant to abrasive wear. The addition of carbon increases lubricity, reducing heat generation and chip welding.

Best Applications For TiCN Coated Cutting Tools: Milling of cast iron, stainless steel, and high-silicon aluminum alloys. Ideal for interrupted cuts and metalworking applications including hard milling where impact resistance is important.

Material Suitability for TiCN Coated Cutting Tools: Carbon steels, tool steels, die steels, and aluminum alloys with high Si content.

Zirconium Nitride (ZrN) Coating

Color: Light gold

Color: Light gold

Hardness: ~2,000–2,200 HV

Max Operating Temp: ~500°C

Non-reactive with aluminum

Key Features Of ZrN Coating: Excellent resistance to built-up edge (BUE), which is common when machining soft, gummy materials. Chemically stable when in contact with aluminum, preventing material transfer and tool sticking.

Best Applications for ZRN Coated Cutting Tools: High-speed machining of non-ferrous metals. Great for precision aluminum finishing, plastics, and brass.

Material Suitability for ZRN Coated Cutting Tools: Pure aluminum, copper, brass, plastics, magnesium, and composite materials.

Aluminum Titanium Nitride (AlTiN) Coating

Color: Black or dark gray

Color: Black or dark gray

Hardness: ~3,200–3,500 HV

Max Operating Temp: ~800–900°C

Oxidation Resistance: Excellent

Key Features of AlTiN Coating: AlTiN excels in high-temperature applications due to its excellent thermal stability and oxidation resistance.The aluminum content forms a protective Al₂O₃ (alumina) layer during cutting, which insulates the tool from heat and reduces crater wear.

Best Applications for AlTiN Coated Cutting Tools: Dry machining and high-speed cutting of hardened steels. Excellent for roughing and semi-finishing operations.

Material Suitability for AlTiN Coated Cutting Tools: Alloy steels, hardened steels (>45 HRC), tool steels, and cast iron.

AlTiSi-based nanocomposite (nACo) Coating

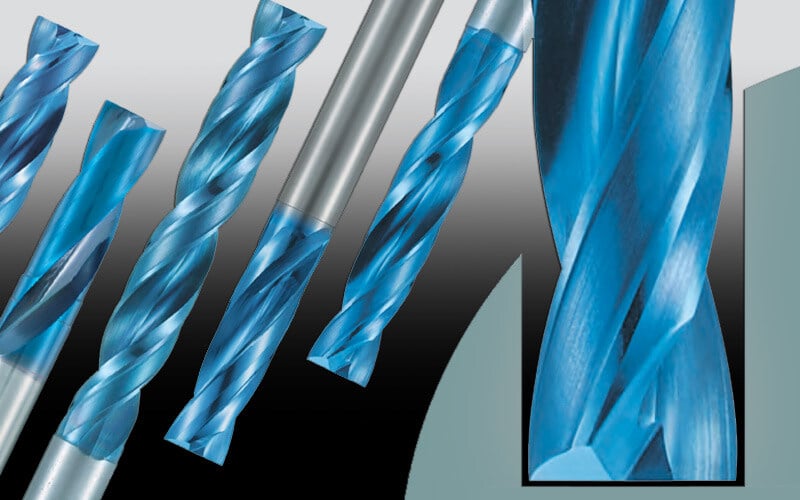

![]() Color: Blue-Violet

Color: Blue-Violet

Hardness: ~4,500 HV

Thermal Conductivity: Low

Friction Coefficient: Low

Key Features of AlTiSi-based nanocomposite (nACo) Coating: High temperature stability, good hardness, and versatility.

Best Applications for AlTiSi-based nanocomposite (nACo) Coating: Well-suited for high-heat applications.

Material Suitability for AlTiSi-based nanocomposite (nACo) Coating: Highly effective for milling and drilling carbon steels, but can also be used with CBN tools.

Diamond Coatings (CVD or PCD)

Color: Dull gray or dark silver

Color: Dull gray or dark silver

Hardness: ~8,000–10,000 HV

Thermal Conductivity: Extremely high

Friction Coefficient: Very low

Key Features of Diamond Coatings (CVD or PCD): Offers unmatched hardness and abrasion resistance—ideal for extremely abrasive materials. Available in chemical vapor deposition (CVD) or polycrystalline diamond (PCD) forms.

Best Applications for Diamond Coatings (CVD or PCD): High-volume machining of abrasive non-metals and composite materials. Ultra-precision finishing in industries such as aerospace, medical, and electronics.

Material Suitability for Diamond Coatings (CVD or PCD): Carbon fiber-reinforced plastics (CFRP), fiberglass, graphite, ceramics, high-silicon aluminum, and abrasive plastics.

Choosing the Right Coating: A Quick Reference

| Material | Recommended Coating |

| Hardened Steel (>45 HRC) | AlTiN |

| High-Si Aluminum | TiCN or Diamond |

| Pure Aluminum, Brass | ZrN |

| CFRP, Composites | Diamond |

| Cast Iron | TiCN or AlTiN |

| Carbon Steels | nACo |

| Tool Steels | AlTiN or TiCN |

Conclusion

Using Microcut USA Made Cutting Tools with the correct abrasion-resistant coating for your material can be the difference between a cutting tool that lasts 500 cuts and one that lasts 5,000. When selecting Microcut End Mills, consider not just the substrate and geometry, but the coating technology as well. Tailoring your coating choice to your work material and machining conditions ensures better surface finishes, reduced downtime, extended tool life, and greater profitability.

For high-performance shops and manufacturers looking to optimize their machining strategies, investing in coated cutting tools isn’t optional—it’s essential. Choose a Microcut USA-Made Cutting Tool with an innovative abrasion-resistant coating to ensure optimal performance. For assistance selection the right coating for your Microcut cutting tool, material, and application, contact the A&M Industrial Metalworking Team.