Tungaloy Ball Nose Finishing End Mill

In the world of precision machining, where the finest details matter, choosing the right cutting tool can make all the difference. One such tool that has gained immense popularity among professionals are the Tungaloy Ball Nose Finishing End Mills. With their exceptional performance and precision, this end mill line has become a go-to choice for engineers and machinists seeking unparalleled results. In this blog post, we will delve into the key features and benefits of Tungaloy Ball Nose Finishing End Mills.

-

Superior Design and Construction: Tungaloy Ball Nose Finishing End Mills stand out for their superior design and construction. Crafted with utmost precision, these end mills features a high-performance carbide substrate combined with Tungaloy's state-of-the-art coating technology. The result is an end mill that delivers exceptional wear resistance, increased tool life, and outstanding cutting performance.

-

Versatile Applications: Tungaloy Ball Nose Finishing End Mills are engineered to excel in a wide range of applications, including profiling, slotting, and contouring. These end mills are particularly well-suited for finishing operations, where surface quality and dimensional accuracy are paramount. Whether you are working with stainless steel, aluminum, or hardened materials, these end mills prove to be a reliable and versatile companion.

-

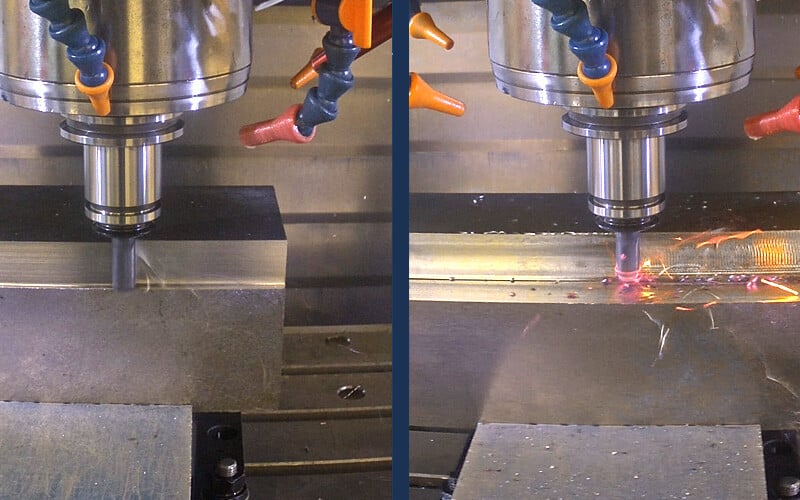

Unmatched Performance: One of the standout features of Tungaloy Ball Nose Finishing End Mills are their impeccable performance. The advanced geometry of the ball nose design ensures smooth and precise cutting, allowing for high-quality surface finishes. The specialized flute design enhances chip evacuation, preventing chip build-up and ensuring optimal cutting conditions. The combination of these features translates into reduced cycle times and improved productivity.

-

Extended Tool Life: When it comes to cutting tools, durability is crucial. Tungaloy Ball Nose Finishing End Mills boast an extended tool life, thanks to their robust construction and advanced coating technology. The combination of a wear-resistant substrate and a specially formulated coating significantly reduces tool wear, resulting in longer intervals between tool changes. This not only saves time but also reduces costs associated with tool replacement.

-

Cost-Effective Solution: While the initial investment in high-quality cutting tools may seem daunting, it is essential to consider the long-term benefits. Tungaloy Ball Nose Finishing End Mills offer a cost-effective solution by providing extended tool life, improved performance, and reduced downtime. With fewer tool changes and enhanced productivity, machinists can achieve higher throughput, leading to cost savings and increased profitability.

Summary

In the competitive world of precision machining, having the right cutting tool for your application is essential for achieving exceptional results. Tungaloy Ball Nose Finishing End Mills are the top choice for professionals seeking superior performance, extended tool life, and precise machining capabilities. With their outstanding design and versatility, Tungaloy Ball Nose Finishing End Mills have become a reliable companion in the pursuit of excellence. Whether you are working on complex profiles or high-precision contours, Tungaloy Ball Nose Finishing End Mills provide outstanding results time and time again.

Tungaloy offers a wide range of boring tools, holemaking tools, milling tools, turning tools, tool systems, and more, that deliver quality, reliability, and performance.

Need Metalworking Assistance Or Tech Support?

Our expert metalworking team can partner with you to evaluate your approach to any application

and improve cycle times, set-up, and productivity. To request technical support or product selection assistance, contact the A&M Industrial Metalworking Team.