Which web sling is the right one for the job?

When it comes to quality lifting slings like the Tuff-Edge III, A&M Industrial stands out as a trusted provider. A lot of technical information goes along with selecting the right material handling sling for the job. A&M is here to ensure you have all the facts to make the best selection. Read on to find more information regarding one of our most highly recommended Lift-All slings.

1) Start by choosing the best material for your lift

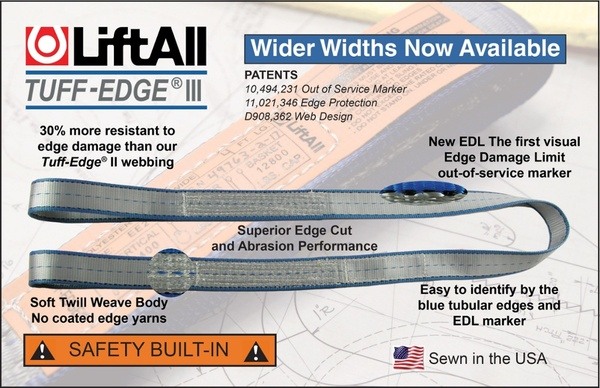

Lift-All’s patented Tuff-Edge® III material offers increased abrasion, edge-cut resistance, and an out-of-service marker that makes inspections easier. With Tuff-Edge III, the softer twill weave body ensures no marring on the load but is strong enough to handle heavy lifts. It provides safety built-in with its tubular edge design and no polymer-coated edges. The change in edge design reduces the possibility of injury when riggers run their hand along the edge. A polymer-coated edge can easily cut the rigger's hand, whereas Tuff-Edge III will not. The chart below explains just how Tuff-Edge III excels in edge-cut performance against the popular versatile workhorse, Webmaster® 1600. Available in 1” to 12” widths and various eye treatments.

Along with web sling material and web width, the number of plies plays an integral role in the rated capacity for each sling. Another reason we prefer Lift-All as a supplier partner is they simplify selecting the right ply and web width with easy-to-read tables like the ones below. The tables provide rated capacity information for the standard Webmaster 1600 and Tuff-Edge III.

| Web Edge Cut Performance Chart | ||

| Webbing Design | Edge Construction | Comparative Web Edge Cut Test Performance Rating |

| Webmaster 1600 Polyester | Standard | Poor |

| Tuff-Edge II | Polymer | Good |

| Tuff-Edge III | Tubular With Reinforced Core | Best |

2) Choose the eye treatment suitable for your lift

Tuff-Edge III is a durable material available for any web-based sling configuration. Tuff-Edge III can accommodate eye treatments such as endless, eye and eye, triangle and choker, and web configurations such as reverse eye and even wide lifts.

The eyes of a web sling are often subjected to the harsh treatment of rough gantry crane hooks. Specialty eye treatments are available to help reduce the wear in the area, thereby extending sling life.

Determine flat or twisted eye, lined at the bearing point or fully lined, wrapped at the bearing point or fully wrapped eye.

3) Sling protection is the next step in sling selection

Always protect synthetic slings from being cut by corners and edges. Lift-All provides cut protection as well as wear protection. Cut protection improves workplace safety, whereas wear protection products extend sling life by reducing abrasive wear. Lift-All’s Edge Defender™ and Edge Defender Flex Plus product line uses patented technology and multiple layers of heavy-duty protection material to produce superior cut protection. Learn more about cut versus wear protection from this video.

When choosing the next web sling for your lift, Lift-All products offer safe options that stand up against harsh lifting conditions. Still not sure which sling material is best for your lift? Lift-All’s sling calculator takes the guesswork out of choosing the right sling.

Need Assistance?

Remember…when you choose Lift-All slings at A&M Industrial, you’re not just purchasing equipment, you’re investing in a partnership that enhances the material handling aspect of your industrial operations and caters to your various needs. Contact your local A&M Industrial rep to learn more and choose Lift-All slings for your next lift!