Boost Your Precision With Precision Brand Adhesive Backed Shim Stock

When it comes to achieving perfect alignment and tight tolerances, machinists know that precision is everything. Whether you're setting up a new machine, performing maintenance, completing a metalworking application or making fine adjustments on the fly, having the right tools and materials can make all the difference. One often overlooked but incredibly useful product in the machinist's toolkit is Precision Brand Adhesive Backed Shim Stock.

What is Adhesive-Backed Shim Stock?

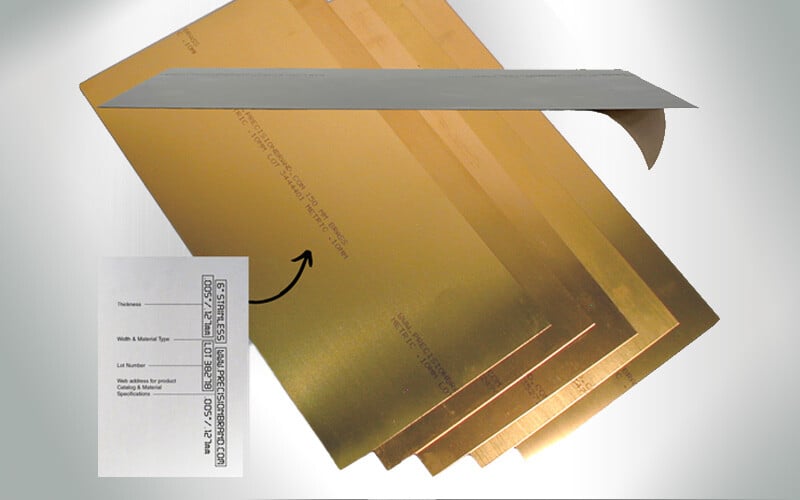

Adhesive-backed shim stock is a thin, flexible material with a thin, .002" thick adhesive layer on one side. It comes in various materials such as steel, stainless steel, brass, blue temper steel and plastic. The adhesive backing makes it easy to apply to surfaces without additional fasteners, providing a quick and effective solution for spacing, leveling, and alignment challenges. Plus, Precision Brand Adhesive Backed Shims, excluding plastic adhesive-backed shim, is branded for easy identification.

Why Machinists Love It

-

Easy Installation: The adhesive backing allows for precise placement, even on vertical or overhead surfaces. There's no need for clamps or fasteners—just peel and stick! Never worry about your shim slipping again!

-

Time-Saver in Repairs: When machines are down, every minute counts. Adhesive-backed shims can be quickly applied to fix misalignments or fill gaps without extensive disassembly.

-

Versatile Material Choices: Whether you need the strength of stainless steel, the flexibility of brass, or the insulating benefits of plastic, there’s a Precision Brand Adhesive Backed Shim for the job.

-

Customizable: Easy to cut and shape with standard shop tools. Machinists can create custom-sized shims for unique applications on the spot.

Adhesive-Backed Shim Stock Applications

-

Machine Setup: When installing or aligning motors, pumps, or gearboxes, adhesive-backed shims provide a quick and reliable way to achieve precise positioning. Precision Brand Adhesive Backed Shims can be applied quickly and stay in place while you reposition or realign equipment as needed.

-

Tool and Die Work: During die setup, these shims can help achieve the perfect clearance, ensuring high-quality parts and reducing tool wear.

-

Vibration Reduction: Applying shims between components can help reduce machine chatter and extend the lifespan of equipment by minimizing wear and tear.

-

Prototype Development: Adhesive backed shims are invaluable when fine-tuning prototype assemblies. Their easy adjustability speeds up the iteration process.

Pro Tips For Machinists

-

Surface Preparation: Clean the surface thoroughly before applying shims to ensure a strong adhesive bond.

-

Layering for Adjustability: If needed, shims can be layered to achieve precise spacing.

-

Storage and Handling: Keep shims stored flat and in a dry area to maintain adhesive quality.

Final Thoughts

Precision Brand Adhesive Backed Shim Stock might not be the flashiest tool in the shop, but its versatility, ease of use, and effectiveness make it a go-to solution for many machining challenges. Whether you’re aligning components, fine-tuning equipment, or making quick repairs, these shims can help keep your operations running smoothly.

Next time you’re facing a tricky alignment or repair task, reach for a sheet of adhesive-backed shim—you might be surprised by how much time and hassle it can save!

More On Adhesive-Backed Shims

Precision Brand Shim is the preferred choice of machinists and metalworking professionals. To see more about Precision Brand Adhesive Backed Shim Stock, including a full list of available materials and sizes, download the Precision Brand Adhesive Backed Shim Guide now, or contact the A&M Industrial Metalworking Team for more information.