How To Choose The Right Norton Grinding Wheel

Today, we're going to dive into one of the most essential tools in any workshop: the grinding wheel. Whether you're a seasoned pro or a newbie in the world of grinding, knowing how to choose the right grinding wheel is crucial for getting the job done efficiently and safely.

Understanding Grinding Wheels:

Before we jump into the nitty-gritty of choosing a grinding wheel, let's take a moment to understand what they are and how they work. Simply put, a grinding wheel is a tool used for a wide variety of metalworking applications including cutting, grinding, or polishing various materials, including metal, wood, or stone. It consists of abrasive particles bonded together in a wheel shape. A grinding wheel can spin at thousands of RPM’s (revolutions per minute), making it an excellent cutting tool for a wide variety of applications.

Factors to Consider When Selecting Grinding Wheels:

When selecting the right Norton Abrasives Grinding Wheel for your application, consider the following factors:

Material Type: Different grinding wheels are designed for specific materials. For example, if you're working on stainless steel, you'll need a grinding wheel specifically formulated for that material. So, before heading to the store, be sure to determine the type of material you'll be working with, and select a grinding wheel with an abrasive grain best suited for that material:

- Ceramic Aluminium Oxide: often referred to as just “Ceramic”, Norton’s ceramic form of aluminium oxide is harder and sharper than conventional abrasive grains. This ceramic grain has a unique microcrystalline structure that is self-sharpening, reducing the regularity that the grinding wheel needs dressing as well and providing a significantly cooler cutting action when in use.

- Silicon Carbide: harder than standard aluminum oxide with a very sharp abrasive grain. It is a versatile material, recommended for grinding relatively soft metals such as aluminum or cast iron but can also be used on extremely hard materials such as cemented carbide.

- Zirconia Alumina: for use in rough grinding applications where high stock removal is required. This grain is associated with high tech resin bonds.

- Aluminum Oxide: recommended for grinding materials of high tensile strength, such as stainless steel and tool steels but it can also be used on some high tensile aluminum and bronze alloys.

Wheel Type: Grinding wheels come in various types, such as straight wheels, cylinder wheels, and tapered wheels. Each type serves a specific purpose, so it's important to choose the right one based on your application. Straight wheels are ideal for surface grinding, while cylinder wheels are great for grinding cylindrical surfaces.

Grit Size: The grit size refers to the size of the abrasive particles embedded in the grinding wheel. It determines the finishing quality and material removal rate. Coarser grits (lower numbers) are suitable for rough grinding, while finer grits (higher numbers) are better for precision grinding or polishing.

Wheel Hardness: The hardness of a grinding wheel affects its durability and cutting ability. It is measured on a scale from A to Z, with A being the softest and Z being the hardest. For general-purpose grinding, medium-hard to hard wheels (H-K) are often recommended.

Wheel Dimensions: Consider the size and shape of the grinding wheel that will best suit your needs. Factors such as diameter, width, and hole size should be considered based on the machine you'll be using and the specific task at hand.

Safety First: Always prioritize safety when selecting a grinding wheel. Ensure that the wheel has the proper speed rating for your grinder and that it meets industry safety standards. Additionally, check for any special instructions or precautions mentioned by the manufacturer.

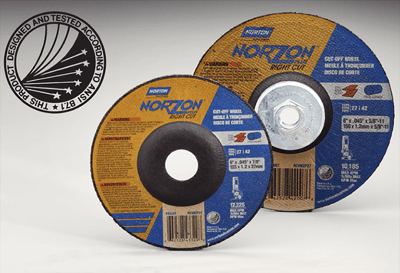

Tested & Proven Quality: While there are grinding wheels that comply with the ANSI Standards and do not have the ANSI Certification Seal, we recommend that you look for the seal when purchasing your grinding wheels. This seal certifies that the grinding wheels you buy have been designed and tested according to American National Standard ANSI B7.1.

Tested & Proven Quality: While there are grinding wheels that comply with the ANSI Standards and do not have the ANSI Certification Seal, we recommend that you look for the seal when purchasing your grinding wheels. This seal certifies that the grinding wheels you buy have been designed and tested according to American National Standard ANSI B7.1.

ANSI requires that most grinding wheels be speed tested at specified speeds above the maximum approved operating speed. These ANSI designed standards and testing procedures improve the wheel’s safety and reliability. Norton Abrasives and grinding wheels have been designed and tested according to American National Standard ANSI B7.1, and bear the ANSI Certification Seal.

Conclusion:

Finding the proper grinding wheel is like finding the perfect dance partner – it makes the entire process smoother, safer, and more enjoyable. By considering factors such as material type, wheel type, grit size, hardness, and dimensions, you can be confident in selecting the ideal grinding wheel for your needs. Contact the A&M Industrial Metalworking Team for additional assistance selecting the right Norton Grinding Wheel for your machining application.

Disclaimer: Refer to manufacturer guidelines and recommendations for specific applications.