Gantry Crane 101: The Basics Of Gantry Cranes

In the world of material handling and heavy lifting, gantry cranes are indispensable workhorses. These robust and versatile material handling cranes are commonly found in various industries, ranging from shipping ports and construction sites to warehouses and manufacturing facilities. This blog will serve as a comprehensive guide to help you understand the basics of gantry cranes – their applications, how they work, different types of gantry cranes and their essential features.

What is a Gantry CraNe Used For?

A gantry crane is a type of overhead crane with supporting legs or wheels that run along tracks or rails on the ground. Unlike traditional overhead cranes that are fixed to the ceiling or structure, gantry cranes provide flexibility and mobility, making them ideal for use in areas where a fixed crane is impractical, including in outdoor worksites, warehouses, manufacturing facilities, and machine shops.

How Does A Gantry CraNe Work?

Gantry cranes work on a simple yet effective principle of leveraging mechanical advantage to lift and move heavy loads. They consist of a horizontal girder (or two girders in the case of a double girder gantry crane) supported by two A-frame legs, which can be either fixed to the ground or equipped with wheels for mobility. The crane's hoisting mechanism is mounted on the girder, allowing it to move horizontally along the length of the crane.

Here's a step-by-step explanation of how gantry cranes work:

-

Load Positioning: Before lifting the load, the gantry crane must be positioned correctly. If it is a rail-mounted gantry crane (RMG) or rubber-tired gantry crane (RTG) used in shipping ports or container yards, it runs along fixed tracks or rubber tires to reach the desired position. For stationary gantry cranes, the load is brought to the crane using forklifts or other material handling equipment.

-

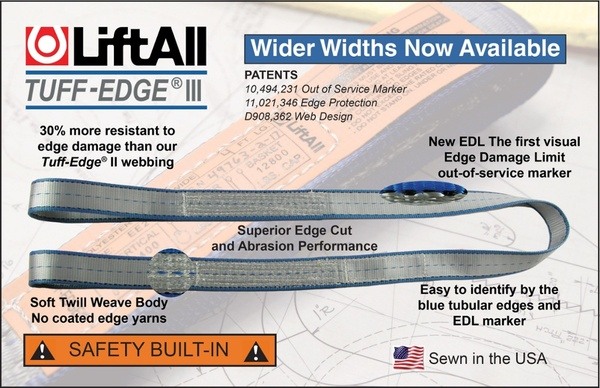

Load Attachment: The load to be lifted is securely attached to a lifting device, which could be a hook, web sling, or specialized lifting attachment depending on the type of load.

-

Lifting Operation: The lifting mechanism of the gantry crane, which includes an electric or hydraulic hoist, is activated. The hoist uses a combination of pulleys, gears, and motors to lift the load. As the hoist's motor turns the drum, the wire rope or chain connected to the lifting device starts to wind up, lifting the load vertically.

-

Horizontal Movement: To move the load horizontally, the entire gantry crane is equipped with a trolley mechanism. The trolley, which holds the hoist, runs along the length of the girder(s) using wheels or a rail system. By moving the trolley back and forth, the load can be precisely positioned along the girder.

-

Vertical Movement (If Applicable): Some gantry cranes, especially adjustable-height gantry cranes, have the ability to adjust their height. This is achieved either through telescoping sections of the A-frame legs or hydraulic systems. The vertical movement enables the crane to lift loads to different heights, accommodating various lifting requirements.

-

Load Placement: Once the load is lifted and in the desired position, the hoisting mechanism is stopped, and the load is carefully placed or lowered to the target location.

-

Load Handling and Safety: During the entire lifting and movement process, operators must follow strict safety protocols. This includes avoiding exceeding the crane's rated lifting capacity, maintaining a safe distance from the load, and utilizing safety features like limit switches and overload protection mechanisms to prevent accidents.

Types of Gantry Cranes:

Gantry cranes come in various configurations, each designed for specific applications:

- Single Girder Gantry Crane: This type of crane features a single horizontal beam (girder) supported by two A-frame legs. It is commonly used for light to moderate lifting tasks in workshops, warehouses, and assembly lines.

- Double Girder Gantry Crane: With two horizontal girders supported by A-frame legs, this crane offers increased lifting capacity and stability. It is suitable for heavy-duty applications in steel yards, construction sites, and shipyards.

- Rubber-Tired Gantry Crane (RTG): These mobile gantry cranes use rubber tires to move along paved surfaces. They are prevalent in shipping ports and container terminals, allowing efficient container handling.

- Rail-Mounted Gantry Crane (RMG): RMGs run on tracks and are commonly used in intermodal yards and container depots, offering high lifting capacities and precise container positioning.

- Adjustable Height Gantry Crane: An adjustable height gantry crane allows for vertical height adjustments, enabling it to accommodate various load sizes and work in spaces with height restrictions. A knock-down adjustable height gantry can be easily assembled and disassembled, saving space when not in use and allowing easier transport.

Gantry Crane Applications

Gantry cranes are highly versatile and can be used in various applications, from loading and unloading containers in ports to heavy lifting in manufacturing and construction. They offer significant advantages in terms of mobility, allowing them to be deployed at different job sites or positions within a facility, enhancing efficiency and flexibility in material handling operations. Gantry cranes can be used across a wide range of industries, including:

- Construction: Gantry cranes aid in lifting heavy construction materials, such as steel beams, concrete blocks, and pre-fabricated structures.

- Shipping and Logistics: Gantry cranes are essential in loading and unloading containers from ships and trucks in ports and container yards.

- Manufacturing: They assist in moving and positioning large machinery and equipment in manufacturing plants.

- Railway Maintenance: Gantry cranes are used for railway track maintenance, lifting heavy components like railway sleepers and track sections.

- Aerospace: Gantry cranes are utilized to assemble and maintain aircraft and aerospace components.

Gantry Crane Features and Safety Considerations:

- Lifting Capacity: Consider the maximum weight the gantry crane needs to lift and choose a crane that meets or exceeds that capacity.

- Span and Height: Determine the required span (distance between legs) and lifting height to ensure the crane fits your workspace.

- Safety Features: Look for features like overload protection, emergency stop buttons, and safety limit switches to prevent accidents.

- Regular Maintenance: Proper maintenance is crucial to ensure the gantry crane operates smoothly and safely. Regularly inspect the crane and its components.

- Operator Training: Ensure that only trained and certified operators handle the gantry crane to minimize the risk of accidents.

Summary

Gantry cranes play a crucial role in optimizing material handling and heavy lifting tasks across various industries. Having a good understanding of the different types of gantry cranes and their applications will empower you to select the perfect crane for your specific requirements. Always prioritize safety, conduct regular maintenance, and provide comprehensive operator training to guarantee the safe operation of gantry cranes. By doing so, you will enhance productivity and minimize any potential downtime, ensuring a seamless workflow.

Need Help Selecting A Gantry Crane?

A&M Industrial's expert material handling team can help you determine the right gantry crane for your application, contact our material handling team for assistance.