How to Reduce Cycle Times When Milling Metal

Nearly daily, our metalworking team gets is tasked with helping a customer reduce cycle times when milling metal. Whether you're a professional machinist or an avid DIYer, these simple tips will help you boost productivity and efficiency. Review the tips below, and contact our expert metalworking team to request additional assistance choosing the right tool for a job, to receive speed and feed recommendations, or to get help with how to approach an application.

Optimize Tool Selection:

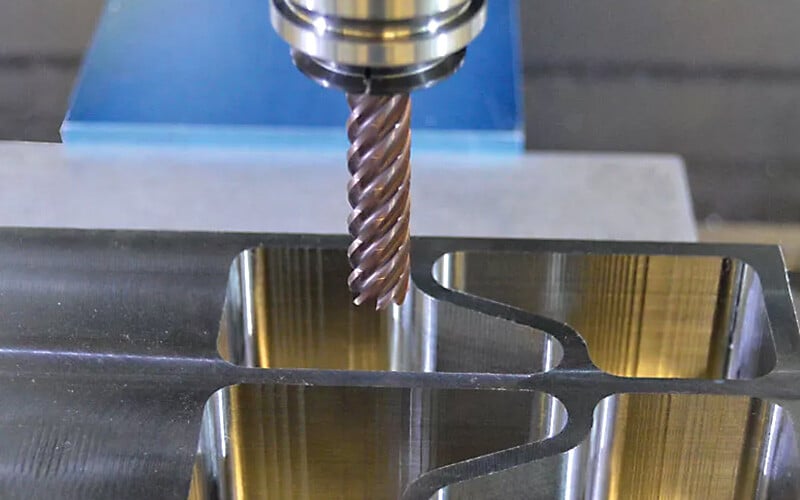

Choosing the right tool is like finding the perfect partner for your milling journey. Different materials and projects require specific tools to achieve maximum efficiency. Look for cutting tools with high-speed capabilities, such as carbide end mills, which are known for their durability and rapid chip evacuation. Don't forget to consider the number of flutes and coatings, as they can significantly impact your cycle time. Consider the hardness and properties of the metal you're milling as well. Contact our metalworking team for tool selection assistance, or check out our aluminum machining and techniques blog or end mill troubleshooting guide for additional useful information. In addition, you can request a machining fluids assessment to ensure you're utilizing the fluids for your milling applications.

Master Your Speeds and Feeds:

Speeds and feeds are like the yin and yang of milling. Finding the perfect balance between these two is crucial for reducing cycle times. Increasing the feed rate while maintaining a suitable spindle speed can help achieve faster metal removal rates without compromising the quality of your work. Refer to manufacturer recommendations for baselines of specific tools or contact our metalworking team to ensure each tool's proper performance and optimize both tool life and workpiece finish.

Embrace High-Speed Machining (HSM):

High-speed machining (HSM) is a technique that utilizes advanced tool paths and optimized cutting conditions to improve productivity. By maintaining consistent chip loads and minimizing tool engagement, HSM can significantly reduce cycle times while extending tool life.

Optimize Tool Path Strategies:

While taking the scenic route may be enjoyable, it's certainly not ideal when it comes to milling metal. Optimizing your tool path strategies can make a world of difference in reducing cycle times. Consider using trochoidal milling, which combines linear and circular movements, minimizing tool wear and improving chip evacuation. Additionally, adaptive milling can dynamically adjust tool paths based on the material's hardness, allowing for faster cutting speeds.

Prioritize Tool Maintenance:

Imagine trying to run a marathon with worn-out sneakers - not a pretty sight! The same goes for milling tools. Regularly inspecting and maintaining your tools can save you both time and money. Dull or damaged tools can slow down your milling process and produce subpar results. Keep those tools sharp and ready for action by sharpening or replacing them as needed. In addition, regular sump maintenance, air tool maintenance, and vise maintenance are critical.

By implementing these tips, you'll be able to reduce cycle times when milling metal and increase your overall productivity. Remember, optimizing tool selection, mastering speeds and feeds, embracing high-speed machining, optimizing tool path strategies, and prioritizing tool maintenance are the key elements to success. Contact our metalworking team, subscribe to this blog, or subscribe to our YouTube channel for more milling tips and all the latest metalworking content.