Top 10 Strategies for Maximizing Tool Life

Maximizing tool life is essential for enhancing productivity and reducing costs in machining operations. Follow these expert tips and implement the top ten strategies for maximizing tool life to help you get the most out of your cutting tools.

1. Cutting Speed Optimization

Cutting speed has a direct impact on tool wear. Operating at excessively high speeds generates excessive heat, which leads to rapid wear. Conversely, running at very low speeds can cause inefficient cutting and accelerated wear. Finding the optimal cutting speed for a specific operation is crucial for extending cutting tool life while maintaining efficiency.

2. Feed Rate Control

The feed rate, which is the distance a cutting tool moves into the workpiece with each revolution, significantly impacts tool wear. Incorrect feed rates—whether too high or too low—can lead to excessive wear. High feed rates may cause chipping and tool breakage, while low feed rates result in rubbing and increased friction. Optimizing the feed rate strikes a balance that reduces tol wear and enhances productivity, each of which is key to running a successful manufacturing business.

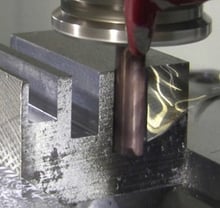

3. Proper Chip Evacuation

Ensuring effective chip evacuation is crucial for extending tool life. Inadequate chip evacuation can result in the recutting of work-hardened chips, which harms the tool. Moreover, chip packing can decrease chip space, elevate cutting forces, and eventually lead to tool breakage. By optimizing cutting parameters, tool geometry, and coolant or lubrication methods, you can achieve proper chip evacuation, thereby reducing cutting tool wear and enhancing productivity.

4. Tool Material Selection

The material being machined significantly affects tool wear. Harder materials typically lead to quicker wear, necessitating durable and wear-resistant tools. Carbide tools, especially those with cemented carbide substrates, are a dependable choice for precision machining. SGS provides top-tier carbide substrates that undergo stringent testing to ensure exceptional performance and durability.

5. Optimized Tool Geometry

In addition to material selection, the geometry of the cutting tool plays a vital role in achieving efficient cutting performance. SGS’s precision tools incorporate advanced designs that boost performance, productivity, and tool longevity. Selecting the appropriate geometry for the specific material and application is essential for prolonging tool life. SGS’s Tooling Matrix assists in choosing the optimal tools for various materials and operations.

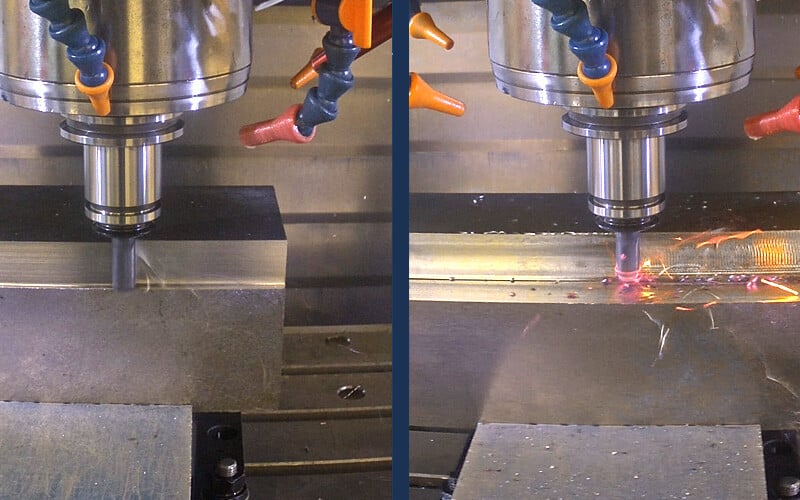

6. Cooling and Lubrication

Effective coolant and lubrication are essential for reducing wear by minimizing friction and heat buildup. Insufficient cooling and lubrication can increase friction, resulting in heat buildup and faster tool wear. To address this, machinists should select the correct type and concentration of coolant and lubricant. For flood coolant applications, it is crucial to distribute the flow between the tip of the cutting edge and the top of the flutes to maximize tool life and increase productivity.

7. Tool Path Optimization

The selected tool path can significantly impact tool life by affecting cutting forces, chip formation, chip evacuation, heat generation, and tool engagement. For instance, trochoidal tool paths can enhance tool life by ensuring smoother entry and exit from the material and maintaining a consistent engagement angle. By optimizing the tool path for the specific tool and application, you can reduce wear and extend tool life.

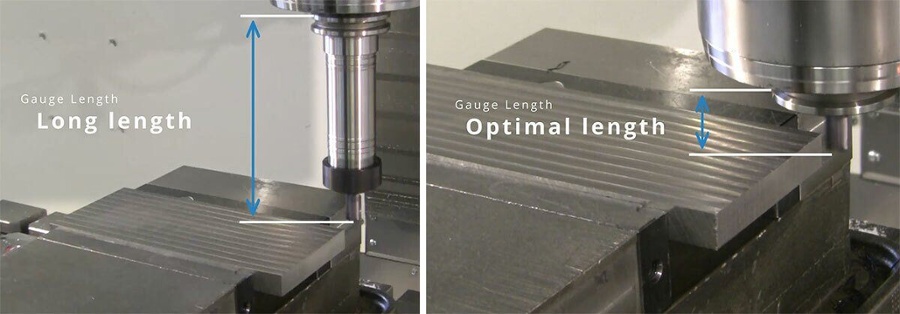

8. Gauge Length Reduction

The gauge length, which is the distance from the end of the tool to the tool holder, has a significant effect on tool life. Longer gauge lengths can lead to deflection, vibration, and concentrated cutting forces, which accelerate wear and may cause tool breakage. Reducing the gauge length improves tool rigidity, decreases deflection and vibration, and evenly distributes cutting forces, thus extending tool life.

9. Fixturing Stability

A well-crafted fixture is crucial for ensuring stability, minimizing vibrations, and maintaining precise workpiece positioning. Inadequate fixtures can cause excessive vibration and movement, leading to increased tool wear. Adopting a strong fixturing strategy reduces wear, enhances cutting performance, and prolongs tool life.

10. Machine Maintenance

Proper machine maintenance is often overlooked but plays a critical role in tool life. Regularly inspecting and maintaining your machinery ensures optimal performance, reducing the risk of excessive vibration, misalignment, or other issues that can lead to accelerated tool wear.

By following these strategies, you can significantly enhance tool life, reduce downtime, and boost overall machining productivity.

Want More Pro Tips & Strategies?

A&M Industrial's Metalworking Team is among the most knowledgable in the industry! Let them put their years of industry experience and expertise to work for you! Contact the A&M Industrial Metalworking Team or request technical support, a service, or assessment today.